Ancient Grains for Optimal Nutrition

Harvest Article 2017 – Spring

Rachel Rose talks with Ian Henderson of Milmore Downs, the oldest continuously- certified Demeter farm in New Zealand, about growing nutritious biodynamic grains and flour.

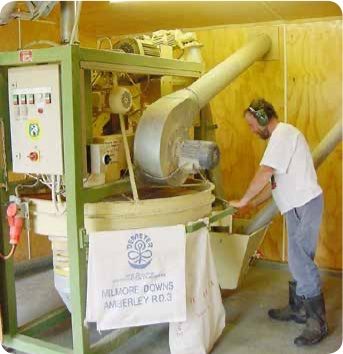

Milmore Downs is a 302 ha mixed farm in Scargill, on the North Canterbury plains. It runs sheep and cattle as well as growing an array of grains: wheat, rye, barley and spelt. The harvest is sold as whole grains and further processed on site, to produce wholegrain flour, flakes and kibbles. Barley is also processed into semolina and pearled. Milmore Downs uses an imported German-made Zentrofan mill, which was the first of its kind in New Zealand.

A Zentrofan mill – sometimes called a cyclone mill – grinds the grain kernel on a fixed natural grinding stone by way of a constantly circulating air current. The whole grain is milled, and the flour has an even, very fine texture.

The benefit may go beyond the material plane though, as farmer Ian Henderson explains. “Steiner said that grains are grasses – grasses are related to the airy constellations – and if you can mill your grain in the air, you allow the elemental world to be a part of the process and you’ll maintain the maximum vitality in the grain.

The Zentrofan mill was designed by a German, Wilhelm Schulte, just after World War II. He was in charge of an orphanage and only given a certain amount of grain to feed his children, who were starving. He knew about this comment of Steiner’s, and he set about trying to make a mill that would make better quality flour. I don’t know how many prototypes there were, but he [eventually built] the Zentrofan mill. When he showed the flour to the experts, they said ‘You’ve killed that flour, it’s dead, it’s too fine!’ But from the same amount of grain, when he fed his children food made with the Zentrofan-milled wheat, they blossomed.

“I think there’s a double effect happening. There’s also the effect of the way it’s milled. It grinds the bran particles quite finely so you can digest them – they’re not bran flakes any more. You can absorb the minerals from it, so it’s no longer just roughage for you.” The nutrients in the bran include iron, magnesium, zinc, calcium, B vitamins and phenolic compounds.

The Henderson family started growing spelt about 20 years ago. Spelt (Triticum dicoccum) is also known as dinkel. It’s existed since 5000 BC and was an important staple in many parts of ancient Europe. It’s a cross between one of the ancient domesticated wheats – possibly emmer wheat – and a wild grass. In Greek mythology, spelt was a gift to the Greeks from the harvest goddess, Demeter. Unlike most grains, it is alkali-forming in the human body. Spelt contains enough gluten to rise well when used for bread or baking, while it also can often be digested by people who show intolerance to modern wheat.

“The wheat protein is made up of several amino acids, which have a relationship each one to the other. Gluten is made up of gliadin and glutenin, along with other amino acids,” says Ian. “This is still conjectural, but in the wheat breeding process, people have been looking to make the straws shorter and stronger and to increase the yield and resistance to fungal rusts – and they haven’t thought about what that’s been doing to other aspects of the plant.

“In Greek mythology, spelt was a gift to the Greeks from the harvest goddess, Demeter”

Ian Henderson

“The ratio between the different amino acids in the protein has shifted as a side effect. I think the problem with modern wheat is that it’s been over-bred. It’s been manipulated – with good intention – but the side effect has been that increasing numbers of people have trouble digesting it.

Ancient spelt has a different gliadin:glutenin ratio compared to wheat. Ian ran some early experiments with a willing friend who was acutely allergic to wheat. Ian sent him four samples of his flour, labelled only A, B, C, D. The results in this case were clear cut; the human guinea pig became very sick after eating the two wheat samples, but greatly enjoyed the spelt samples without ill effect. Other customers report the same benefit, but it’s not universal, and people need to check carefully for themselves, says Ian. “Spelt is not for coeliacs,” he cautions.

Milmore’s team pioneered the growing of spelt in New Zealand. Ian’s long been a fan; with relish he quotes Hildegard von Bingen, who in the 12th century declared spelt made one “fat of blood.”

The first challenge for Milmore was sourcing seed. They discovered that some had previously been imported under strict quarantine measures, intensely scrutinised during growth, harvest and processing. The importers’ enthusiasm for the project had lapsed at some point, and by the time Ian got wind of it, most of the harvested grain had been fed out to stock. The last couple of sacks were stashed in the back of a shed; Ian tracked it down and this became the base of the crop grown today. “It’s quite a narrow gene base,” Ian notes. “We have sought to import more, but it hasn’t happened yet.”

Growing spelt also has its challenges. “It’s a covered grain, with a very tight husk,” explains Ian. That does mean it’s not vulnerable to birds, but it has to be hulled. “We found some custom-made spelt hulling machinery in the south of Germany, and imported it.” Spelt is very low yielding compared to modern wheat. Combined with the extra processing required, this means it is more expensive to produce than modern wheat.

Milmore Downs’ grains are both Demeter and BioGro certified. Its customers are loyal and enthusiastic about the quality. There are a few farm-gate (or mill-side) sales, if customers are passing through on their way to Christchurch. Orders by mail and fax have been replaced by those sent via email or the farm’s website.

“Our biggest market segment now is probably bakers,” says Ian. “Every month, we’re shipping hundreds of kilos of grain to bakeries around New Zealand. They’re enthusiastic about the product and they are making really good breads; it’s a win for everyone.”